Custom process

Custom process

Step 1: Design consulting

Original design

Perhaps you want something original, but you don't know where to start? As long as you can draw a simple diagram to express your ideas, we will make professional design modifications based on your hand drawn drawings while maintaining your original creativity, striving to achieve the desired effect. Make it have a more perfect wearing visual effect on a unique basis, helping you complete the design creativity you want. It can also help you discover jewelry styles that are attractive to you. Our designers will browse our rich jewelry collection with you to help you discover the design elements you like. Once our designers help you discover possibilities, we will design an original jewelry that fits your lifestyle and budget.

Creative design

If you are a creative talent and have your own design drawings or 3D modeling source files, your design drawings or 3D modeling source files are already very complete and do not need to be modified. We can help you integrate your ideas into precious metals and gemstones. Our designers can work with you to study feasibility, durability, and affordability. We will make it according to the drawings, dimensions, weight, and other information you provide, and strive to be consistent with the drawings! We will ultimately create an original and exquisite jewelry for you.

Modify existing design

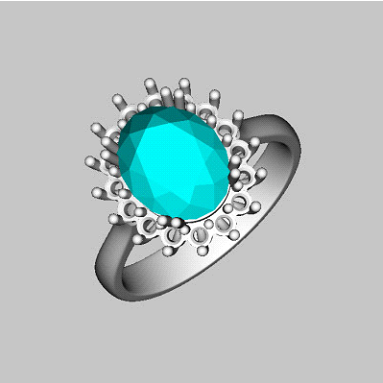

The inspiration for custom design usually comes from existing jewelry. You may come across a piece of jewelry that you like but want to add your own ideas to it. Based on the pictures you provide and your requirements, we can combine the two or more to create the style you want but prefer gemstones with different shapes, sizes, or colors. Generally, it is possible to modify thinner or thicker, longer or shorter, higher or shorter, larger or smaller, or prefer different textures or patterns based on existing products. We often try our best to make similar jewelry at a price that fits our budget. You may even have found a perfect design beyond the finish. Simply changing the type of gemstone or using different precious metals may be enough to meet your personal taste.

Copy a piece of jewelry

Many of our clients have copied family heirlooms. In some cases, additional jewelry may also be made for another family member. Some of my favorite jewelry is lost or worn out and needs to be replaced. Our design team can redesign or replicate most jewelry for you, as long as copying the product does not involve trademark or patent infringement. If the gemstones or materials of the heirloom have emotional value, you may want to restore the original jewelry. If that's the case, you may be more willing to check if the item has been repaired. We will study the safest possible repair methods, faithful to the original materials and design, while ensuring safe wearing.

Our jewelry design guarantees

We have a team of jewelry designers and 3D artists, as well as a team of production process consultants. When you start consulting with us, you will be paired with one of our design consultants who will assist you in enriching design details and weighing various options. Once your design consultant obtains the required information, they will collaborate with our artist team to create renderings of your work based on the information you provide us. You will have the opportunity to review the design and provide feedback, and you can participate in every step and decision of the custom jewelry design process. Before creating the 3D model of your design, we will require you to pay a deposit, which will be used to cover the final cost of your work. When creating your design, we will work at your pace. Some clients only need to exchange some information with us - we usually prepare to produce their works within a few days. Others may be more willing to design and iterate with us for weeks or even months. Our primary goal is to exceed your expectations while creating the customized jewelry of your dreams. Nowadays, technology makes custom jewelry design transactions on a global scale easier until you are satisfied.

Step 2: Computer assisted jewelry design

All design creativity originates from hand drawing. Today, computer CAD digital modeling and rendering technology has become quite mature, and hand drawing ability has always been a necessary skill for designers. However, with the development of intelligence in the jewelry industry, 3D modeling software has been widely used in the jewelry design industry. Jewelry modeling, as a core skill that connects design, production, and promotion, has created favorable opportunities for the digitalization and intelligence of the jewelry industry. Traditional hand-painted jewelry is no longer sufficient for jewelry production. After communicating with you, we have learned about your design requirements. Our next step is to create a jewelry design rendering in computer-aided jewelry design software (CAD). At this point, you may say why there is no sketch section? Because our designers are proficient in using computer aided jewelry design software, using this computer-aided jewelry design technology can generate accurate 3D models of the design. CAD rendering will be presented to you via email. The advantage of doing so is that it can tell you the weight of the jewelry you are designing, the number of stones, and other accurate data. The quality of sketch sketches depends entirely on personal drawing skills, and sketch sketches cannot be output for production. At the same time, it can also avoid situations where sketch sketches look good but cannot be achieved in production technology. Using computer-aided jewelry design software (CAD) can completely avoid this situation.

Step 3: 3-D Hard Wax Model

The approved computer-aided jewelry design files are sent to a 3D printer, which generates hard wax models of jewelry pieces with precise dimensions. Alternatively, a 3D wax image can be sent via email for approval; It depends on what is considered appropriate. After obtaining approval, we will continue to use the precious metal you have chosen to cast your customized jewelry pieces.

Step 4: Customized jewelry ring assembly process: Casting, pre precision processing, assembly, manufacturing, stone inlay, and final precision processing

Your custom jewelry creation is lifelike! Once the 3D hard wax model is approved by you, it will be cast into the precious metal of your choice. The most commonly used precious metals for casting using wax loss casting method (also known as precision casting) are 14kt gold, 18kt gold, or platinum. The main work of mold execution is to modify and repair workpiece defects, shape and weld the workpiece, preliminarily polish the surface of the casting, assemble jewelry accessories, and so on. Metal castings undergo filing and pre finishing to remove rough edges and sides. Once the mold is completed, immediately enter the inlay process. The main process is to fix the main stone and supporting stone on their respective inlays, which is a very important precision process. If the jewelry design includes assembly, manufacturing, and gemstone inlay, the final polishing is carried out after the inlay is completed. Ensure that the metal surface is as shiny as a mirror. Finally, use laser marking equipment to perform the engraving process at the designated location.

Quality inspection, the design team not only needs to conduct quality inspection on the final product, but also needs to control the quality of each stage of jewelry manufacturing, which is absolutely necessary for a perfect design. Quality Inspection - Check the craftsmanship quality of each claw and mouthpiece. All custom jewelry pieces have final detail treatments, which may include satin, matte, high polishing, manual carving, machine carving, etc.

Step 5: Complete Customized Jewelry

Completed: Final Jewelry Design

Exciting part! The final customized jewelry is ready for shipment.

Final step: Global insurance transportation

Onlinecustomjewelry.com provides tracked insurance transportation worldwide. For more information, please refer to our transportation policy.